FAQ Questions

EPS-Concrete blocks offer better insulation, fire resistance, and durability compared to traditional cement-based blocks. They are also lightweight and easy to handle.

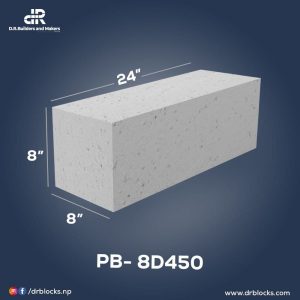

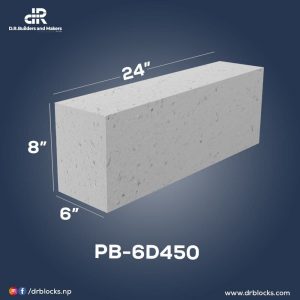

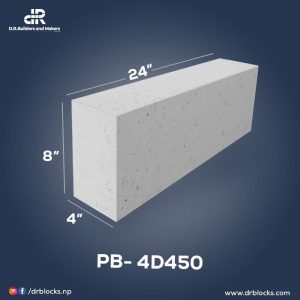

EPS-Concrete blocks can be manufactured in densities ranging from 150 to 650kg/m3, depending on the requirement.

EPS-Concrete blocks can be used for internal and external walls, casting floors, roof slopes, and insulation blocks.

EPS granules are expanded, mixed with high-quality OPC cement, water, and special chemicals to produce blocks of different sizes and densities.

EPS-Concrete blocks are different from traditional cement-based blocks because they are made using expanded polystyrene beads and special chemicals.

EPS-Concrete blocks are eco-friendly because they use less cement compared to traditional cement-based blocks, which reduces carbon emissions.

Yes, EPS-Concrete blocks can be customized according to the specific requirements of the customer.

EPS-Concrete blocks may cost slightly more than traditional cement-based blocks, but they offer better insulation and durability, which can result in long-term cost savings.

EPS-Concrete blocks are eco-friendly and can contribute to sustainable construction practices by reducing carbon emissions and conserving energy.